Thanks to our sponsors, trade exhibitors & visitors for making the 2024 show, great!

BROOKE BOND TROJAN VAN

This one-ton Trojan van was manufactured in the Trojan works Croydon in August 1955 for the Brooke Bond tea company.

They had a number of these, used for tea delivery to local shops. Brooke bond owned the van through to 1963 in London then moved it to Derby where it stayed to 1967.

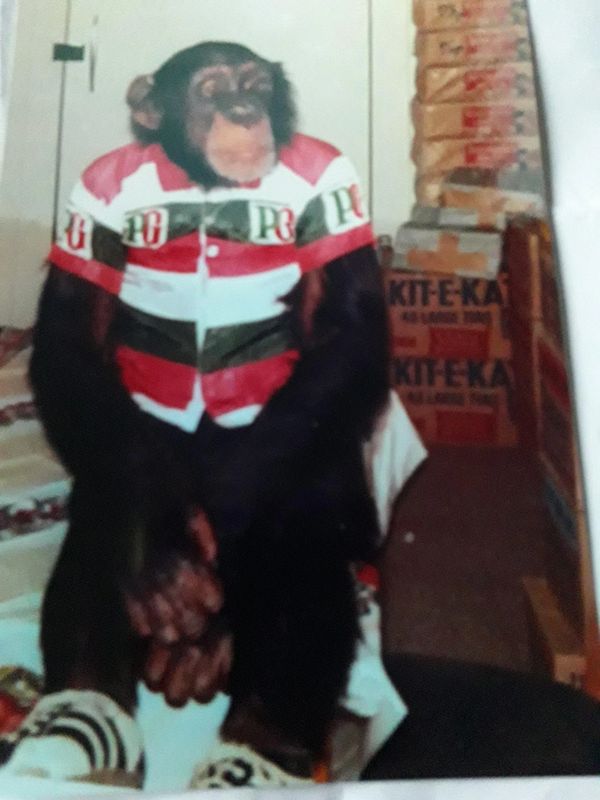

It was sometime accompanied by one of the Brooke Bond chimps. He lived with one of the drivers and was used in sales promotions and tv advertising.

The Trojan was then sold and came to Suffolk it had a towbar fitted at some time but never lost its original Brooke Bond livery. It has not been on the road since 1978.

When I became owner in 2001, it was in a very poor condition having stood out uncovered for 20 plus years, I wasn't any kinder to it.

As when I received it, the chassis had completely rusted through under the driver's floor, leaving the engine sitting on the axle and the spring hanger pushing through the wooden floor. The rest of the van was no better, and I too left it standing uncovered for many years.

At the beginning of Covid lockdown March 2020 it was time to clean up the garden, and decide on the future of the van.

The Trojan Owners club had little interest in post war vans being primarily about the pre-war two stroke cars.

Upon asking about Valuation, they suggested a value of around £500 as it was, if it had a working engine, which it didn't. Then a Value of £500 restored.

That's not a lot of encouragement to save the van!

However, after clearing all kinds of rubbish and undergrowth from around and in it, and with much prodding, poking and contemplation along with as much negativity the wife could muster, the decision was made.

We will keep our promise to the previous owner and restore it.

I received many pictures that were taken during the disassembly, but sadly mostly of irrelevant parts and not enough of critical details.

Then after only six weeks we were called back to work, with customers complaining they needed our products to increase home delivery capacity.

At least I had made a start.

These Vans are a wooden frame with an outer coat of sheet metal, sitting on a steel ladder chassis.

They are powered by the Perkins P3.144 engine, which is approx. 2.5 litre, giving 35Hp through a 3-speed gearbox.

The Hydraulic drum braking is by Lockheed.

The restoration or rust-oration or rot-oration depending on what part you are working on, how do I keep three years at 20hrs per week brief!!

Everything was re worked, re made or repaired.

The wooden frame was almost all remade, so much dry rot with those yellow spreading fungus, so much wood worm that some had completely disintegrated, so impossible to save as patterns.

Most people would think ash to be the correct timber, but it's not in this case, these Van's use BC pine (British Colombian pine) straight grained strong softwood.

On asking a friend, also with some joinery experience about sourcing some, he said no problem, "I've have a stack of reclaimed BC Pine been sitting in my workshop for 30 years if that's any good to you." That's me all over it takes longer to use reclaim, and you get a lot of waste, yet it's more interesting, and fitted with my aim to keep the budget to a minimum.

The side frames and the roof frame were relatively easy.

But remaking the screen surround, and front door hinge post required clamping the repaired doors to the side frames and building the rest to fit.

The metal sheets covering the van were again reclaimed materials from a dismantle spray shop. It took time to make and weld in the repair panels for the outer wings.

Making new inner wings and welding them to the outer in a jig. The front wings being inner and outer joined together to form a box. Then forming new apertures for the headlamps.

It's just impossible to put down all the complications, extensive work and setbacks but I have loads of photos. The bonnet was made from scratch with the curves put in with a hand made former and the louver vents cut and hammered in.

The main Chassis with sections completely rusted out.

I measured up and drew out the sections I needed to get made, to rebuild it both to match the required section and strengthening sections to fit inside them to improve the joints.

Looking round for parts I found another van, this was an abandoned project that had changed hands a few times.

But the best bit, it had a repaired and Galvanised chassis, the bad bit, it was in St Austal Cornwall some 6 and half hours away 362 miles.

After enquiring about professional transport for a flat pack vehicle mostly in boxes etc and getting no takers, I asked a friend (as you do) he said yes, "no problem we will be much better with the triple axle flatbed trailer rather than the car transporter trailer it help save all the bits."

It's a long story but we were there and back in the day starting at 2am he did all the driving now that's a friend.

That gave me a boost I had something to build on.

The wife who normally backs me in all I do, was still pointing out at every opportunity the waste of time that I was spending on the van did start to come round a little.

So in February 2021 with significant snow on the ground and an igloo built, (just something I do on the park when there is enough snow) Chris the wife said what about those seats?

Now Chris has been a sewing machinist since school (we won't say when that was) so very capable of remaking the seats.

I jumped at the opportunity cut some new ply base boards and supports and Chris after cutting foam and making paper templates, manufactured the seats.

What a lovely job they've turned out too!

The engine I knew was bad!

I wired the starter (24volts) to spin it fast enough to start and ran the van to work each day and out at weekends for a month hoping it may improve, but no luck.

We left a trail of blue smoke along the road and a good pool of oil when we stopped. Hills were a interesting challenge.

I rebuilt my spare engine, new liners, new pistons, crank ground, timing chain and tensioner so that's running fine.

The gearbox was no better with screaming bearings and no synchromesh on second.

Rebuilt the gearbox with donor parts and new bearings that's now so much better.

If only somebody had told me how much vibration to except from those early inherently unbalanced 3 Cylinder engines it makes you teeth rattle until you get to a comfortable 45-50mph.

Anyway, it's on the road it must have done 3000miles by now and seem settled.

There are always things to do on an old vehicle.

Thanks for reading, and hope I've not sent you to sleep,

Happy Restoring and Driving to all,

Julian 😊

Classics at Glemham

Glemham Hall, Little Glemham, Woodbridge, UK

Cookie

This website uses cookies. By continuing to use this site, you accept our use of cookies. Privacy Policy